Safety Benefits

Here are some of the “green and gold” comparisons of PropX

versus conventional and other containerized solutions

Green

If the industry has a completion project that takes 3 months, but we can get that same project done in 3 weeks, we have dramatically decreased the impact to the surrounding communities.

The PropX solution has the fastest unload delivery time in the industry. The detachment of the storage mechanism from the method of transport provides the most consistent and fastest wellsite delivery times. This allows our customers to have better assurance that wellsite supply and demand are matched.

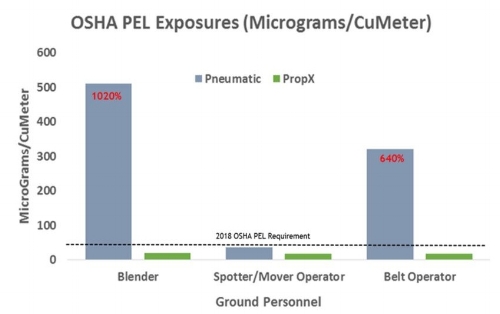

The minimization of truck traffic and traffic jams means no trucks idling for hours, creating air pollution while waiting for their turn to blow off their load of sand. Pneumatic blowers used to unload conventional sand transports are loud, slow, inconsistent and create a significant amount of dust.

PropX’s gravity driven delivery system to the blender along with our fully enclosed conveying system, does not require pneumatic blowers, resulting in an operation which generates very little noise or dust. Furthermore, PropX’s wet sand delivery system enables operators & service companies alike to eliminate this risk entirely.

Since less dust is generated from sand transfer activities, the risks associated with silicosis are dramatically reduced, ensuring a better environment for the health of your workers and better relations with nearby communities and homeowners.

Gold

In today’s competitive market, every dollar counts, and in the case of proppant (which is the largest cost component of a modern frac job), fractions of a penny per pound count. The PropX solution lowers the cost of last mile trucking which can amount to up to half of the total cost of proppant delivered to the wellhead. The ability to unload and load sand containers in less than 5 minutes (versus 45 minutes for the same proppant mass with pneumatic transfer) dramatically reduces the truck “staging” problem and the resultant waiting time or demurrage fees charge by the truckers while standing by waiting on their turn to unload. Even if demurrage is not charged, inconsistent delivery time at the wellsite creates problems consistently supplying a modern frac job. Similar to how a traffic jam has a slinky effect, long wellsite delivery times cause inconsistency of supply leading to higher cost and larger risk of frac downtime.

A low variance of wellsite delivery time in a crucial component for a successful last mile operation of a modern high throughput frac operation. Additionally, PropX containers are smaller, which allows two containers hauled per load. This provides a higher average load volume than other single box competitors. Because the box size is smaller, it allows the use of a smaller, more nimble forklift which increases visibility and safety.

We're Social

Come Visit Us

Please Contact Us For Information Regarding Our Preliminary Tests On "Respirable Dust And Crystalline Free Silica Dust Exposure Levels"